Everyone wants to do a good job or DEG Regeneration Drama

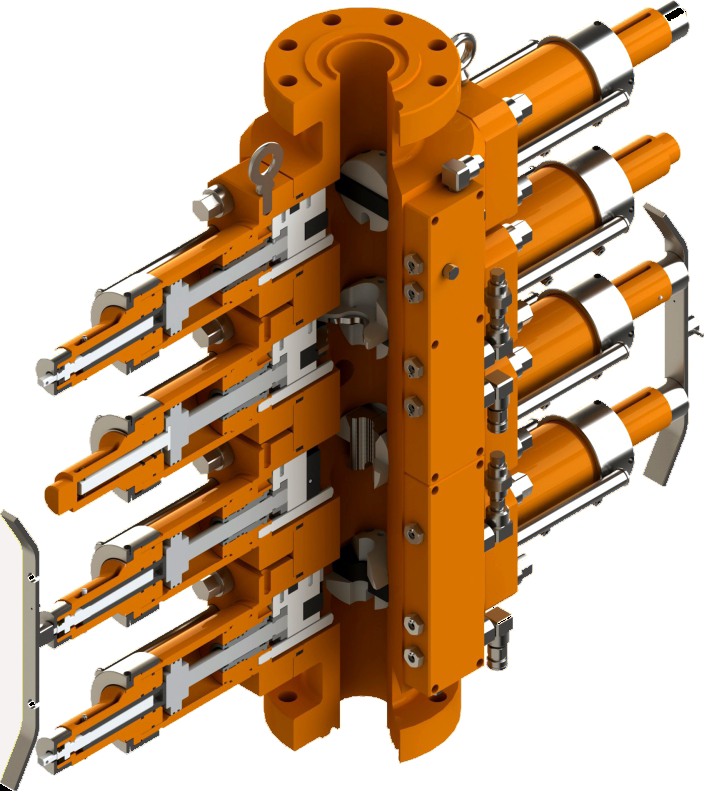

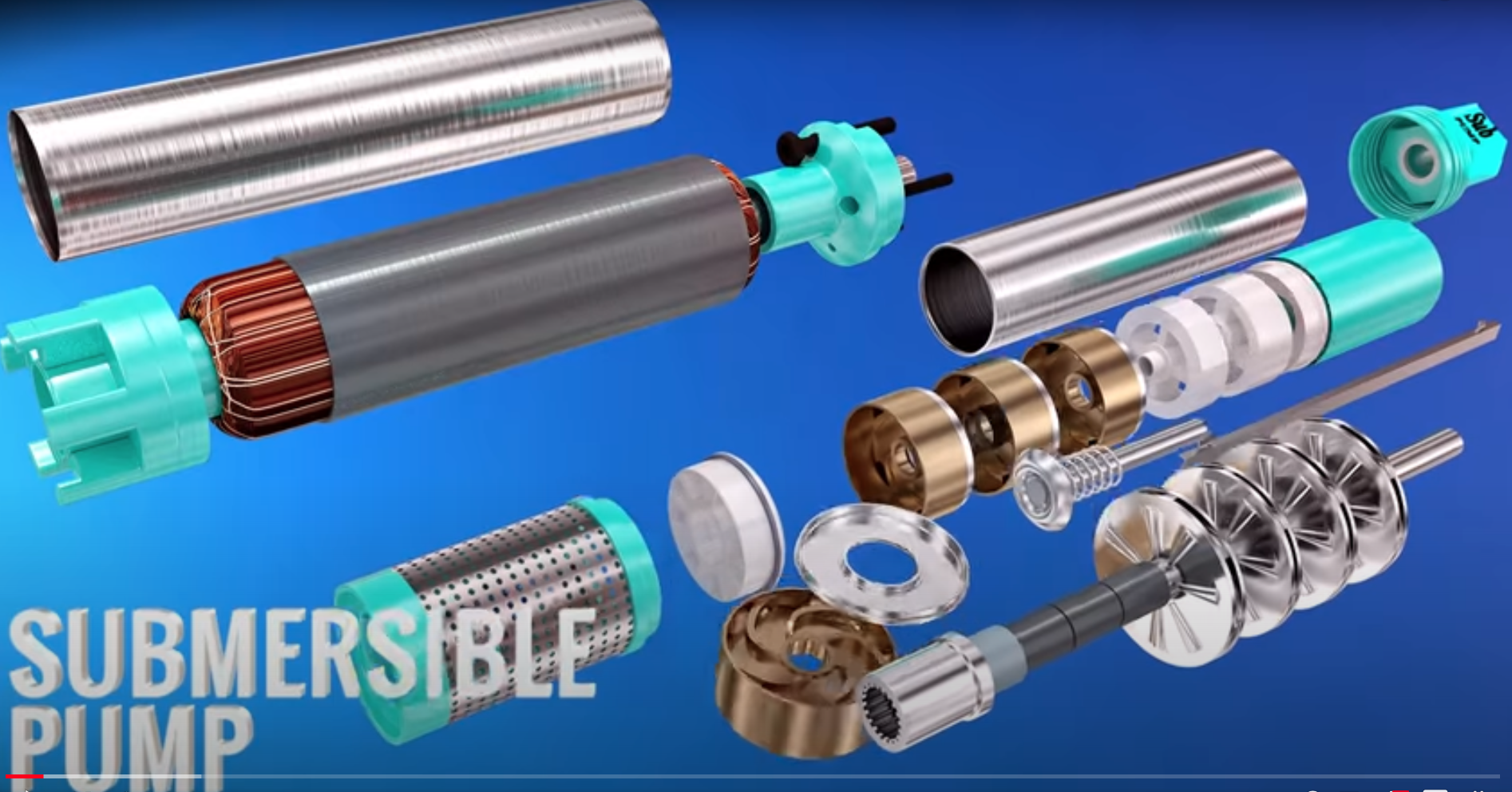

Process Equipment

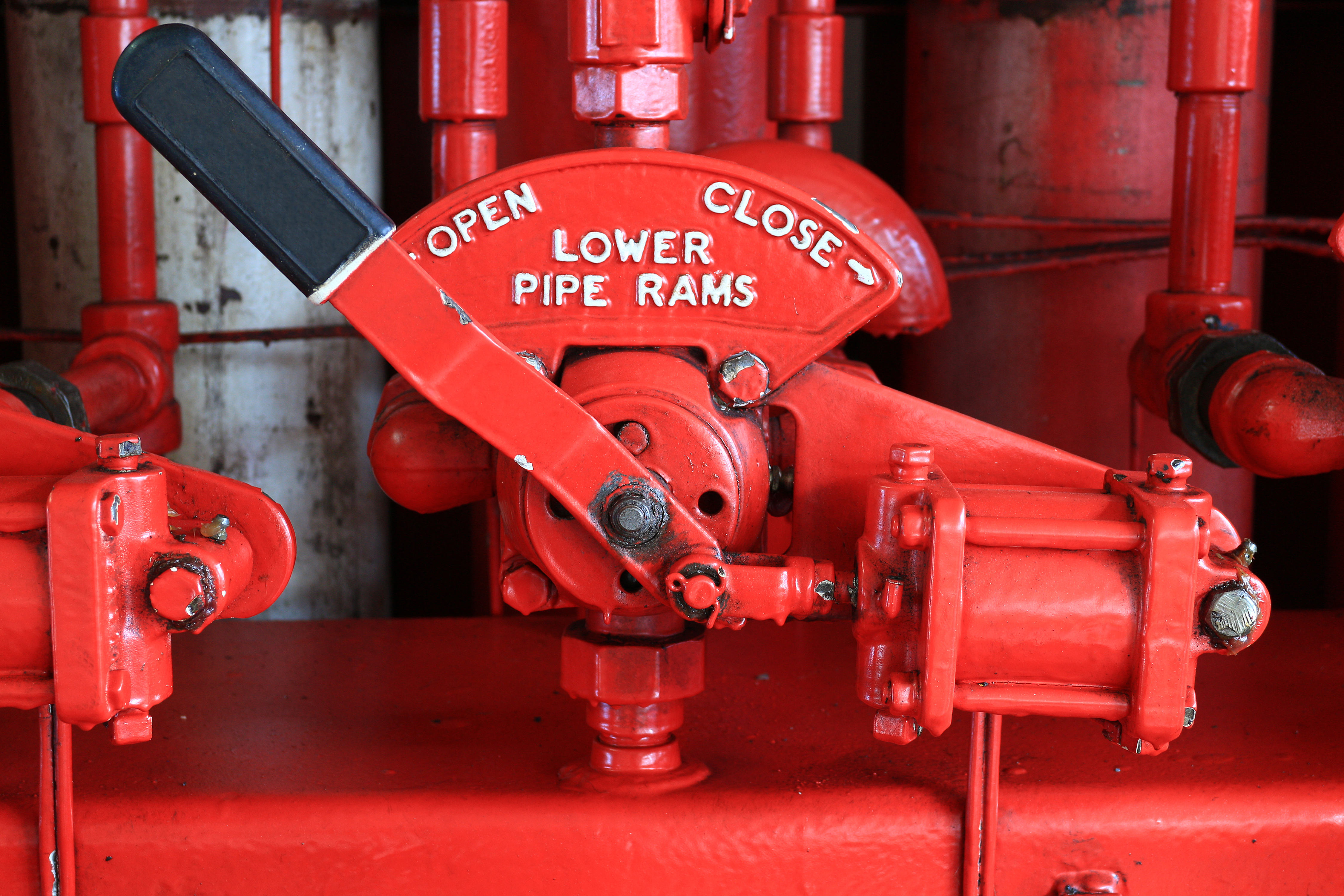

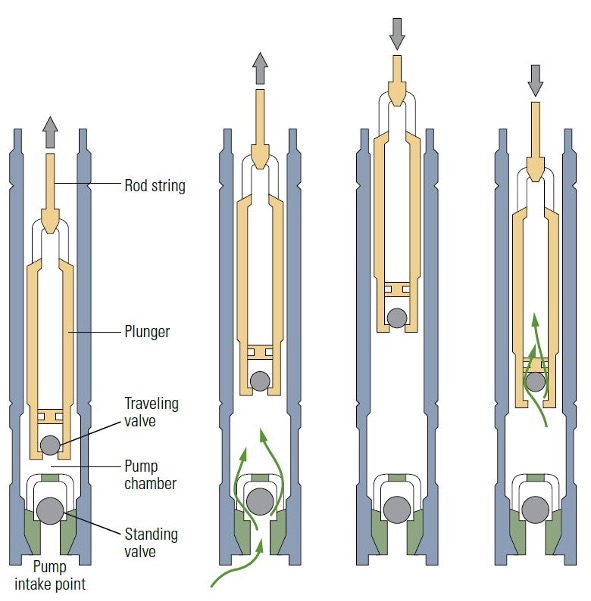

I had just been put in charge of the Facilities Engineering department and I found the job great - working with lots of production, maintenance, and operations people. My manager came to me with an issue that a vendor had not done the work they were supposed to do, took the money for the job, delivered the wrong equipment, and refused to help commission and fix the system. The first step was to figure out what this project was all about. The company was using di-etheylene glycol (DEG) to carry corrosion inhibitor from the wells to the gas treatment facility, as well as binding any free water to avoid hydrates. At the facility the glycol was re-generated by heating the glycol to boil off the water from the glycol (returning it to Lean Glycol). The lean DEG was then returned to the field and re-injected at different wellsites. It was mandated two years previous that the existing DEG regeneration system did not meet standards and would have to be replaced with a new system. The first year this was agreed was a tough one in the industry, so it was almost immediately cut from the budget. The following year it was permitted to have study work done, but at a fraction of the required engineering cost. The year that it was scheduled to be installed, engineering began, and consultants were hired to execute the project and pressure was placed on the organization to get this now hyper-critical regulatory issue dealt with.

Everyone wants to do a good job or DEG Regeneration Drama

Process Equipment

I had just been put in charge of the Facilities Engineering department and I found the job great - working with lots of production, maintenance, and operations people. My manager came to me with an issue that a vendor had not done the work they were supposed to do, took the money for the job, delivered the wrong equipment, and refused to help commission and fix the system. The first step was to figure out what this project was all about. The company was using di-etheylene glycol (DEG) to carry corrosion inhibitor from the wells to the gas treatment facility, as well as binding any free water to avoid hydrates. At the facility the glycol was re-generated by heating the glycol to boil off the water from the glycol (returning it to Lean Glycol). The lean DEG was then returned to the field and re-injected at different wellsites. It was mandated two years previous that the existing DEG regeneration system did not meet standards and would have to be replaced with a new system. The first year this was agreed was a tough one in the industry, so it was almost immediately cut from the budget. The following year it was permitted to have study work done, but at a fraction of the required engineering cost. The year that it was scheduled to be installed, engineering began, and consultants were hired to execute the project and pressure was placed on the organization to get this now hyper-critical regulatory issue dealt with.