The hard hat is a symbol of hard work

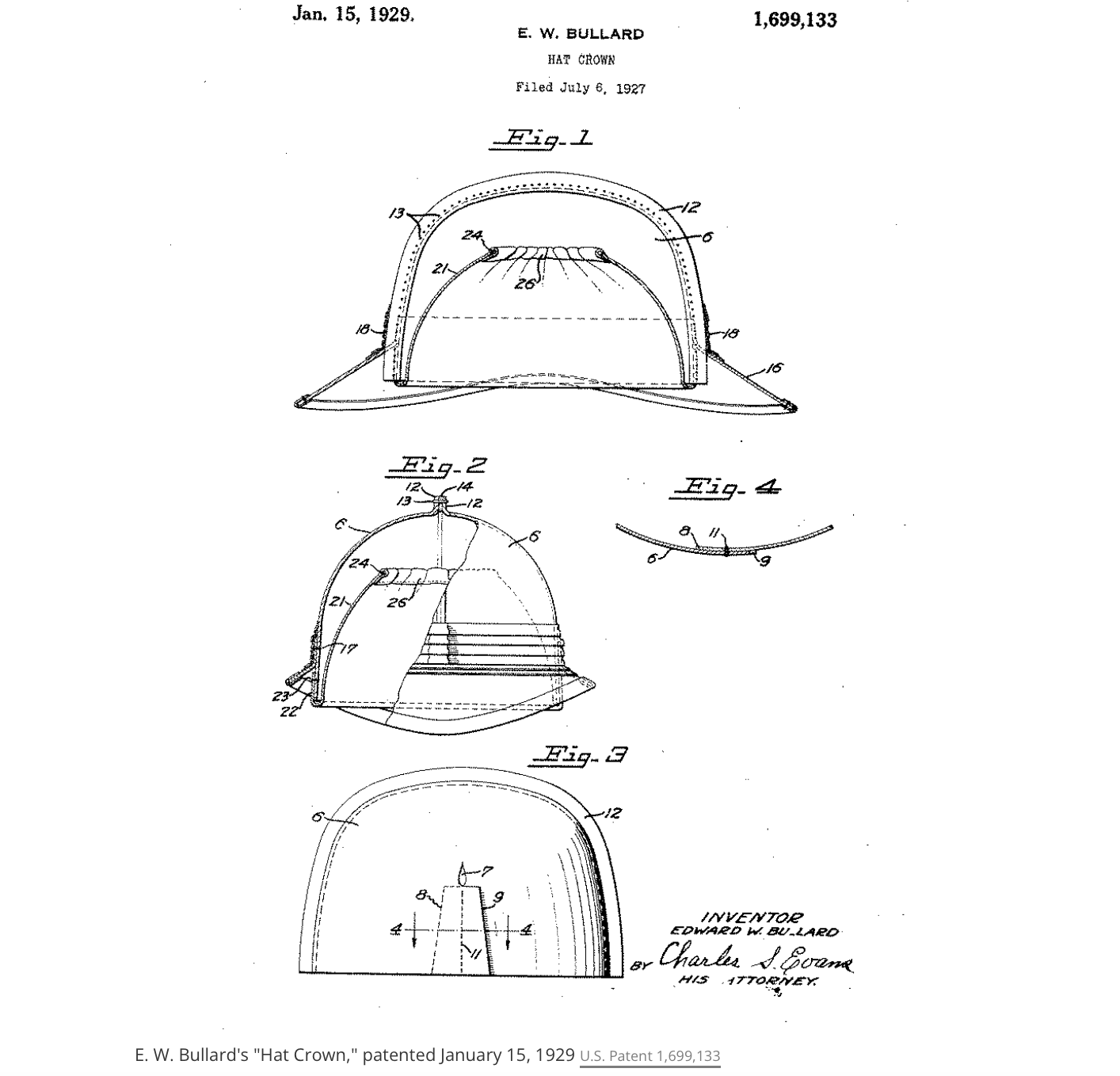

The “hard boiled hat” was invented by Edward Bullard in 1919. A hardhat is a type of protective headgear that is worn by workers in the oil and gas industry to protect their head from falling objects, electrical hazards and other potential hazards that may occur on a drilling site. Hardhats are typically made of high-density polyethylene (HDPE) or other durable materials that can withstand impact and penetration. They are designed to provide a high level of protection to the head and face while allowing the worker to see and hear clearly. The typical hardhat used in oil drilling has several key components, including: • The shell: The shell is the outermost layer of the hardhat and is typically made of HDPE or other durable materials that can withstand impact and penetration. • The suspension system: The suspension system is the internal support system of the hardhat that holds it securely on the head and provides a comfortable fit. It is typically made of a combination of straps, webbing, and other materials that can be adjusted to fit the head snugly. • The headband: The headband is the internal band that sits on the forehead, helping to distribute the weight of the hardhat evenly around the head. • The ear muffs: Many hardhats have the option of adding earmuffs or earplugs to protect the worker from excessive noise. • The face shield: Some hardhats have the option of adding a face shield to protect the worker from flying debris and other hazards.

The engineering specifications for the hardhat used in oil drilling are: • Material: typically HDPE • Impact resistance: typically able to withstand impact of up to 50 ft-lbs • Penetration resistance: typically able to withstand penetration of up to 1.2 inches • Standard: OSHA 29 CFR 1910.135 and ANSI Z89.1

The hardhat used in oil drilling is designed to be both durable and efficient, with a range of features that make it well-suited for use in the oil and gas industry. Its ability to withstand impact and penetration and to protect the head and face from falling objects and other hazards make it a critical component in ensuring safety in drilling sites. The hardhat's suspension system and headband provide a comfortable fit, allowing the worker to wear it for extended periods of time. The option of adding earmuffs or earplugs and face shield to the hardhat provide an additional level of protection. The standardization of the hardhat makes it easy to find a replacement or upgrade. The hardhat is a critical component in the oil and gas industry as it ensures the safety of the workers on site.

Why do drillers have wide brimmed hard hats?

Rig crews typically wear a wide brimmed Hardhat rather than a standard hardhat more common in production operations because the wide brim keeps fluid from going down the back of your neck. This can protect against ran and the elements, but it is mostly for protection against wellborn fluids and chemicals that may spray from the well and drop back down on the rig crew...and, the look cooler!

You may also like

Https://i.pinimg.com/originals/e9/66/51/e9665141082583533d0d6220ec04b80e.jpg

Https://www.smithsonianmag.com/innovation/history-hard-hat-180974238/

The goal for 'Ballycatter Tech' is giving high value content and offering the best experience every day.