How does a rod pump work?

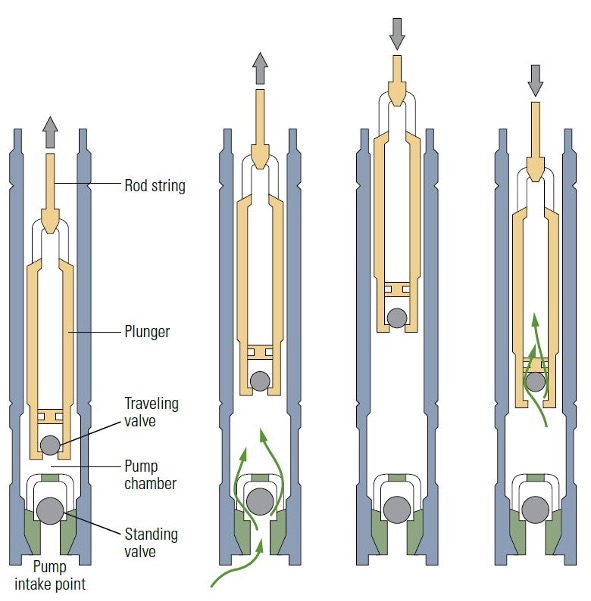

The familiar pumpjack can be found around the world in oilfields from Texas to Beverly Hills to France. Why are pumpjacks so popular? Why are pumpjacks the go-to technology for the oil and gas industry? In short, pumpjacks (and rod pumps) are an efficient, simple and reliable means of pumping fluid from the subsurface. The pumpjack translates circular motion from an electric or gas engine into an up and down motion of a steel rod string. As the pumpjack motor rotates, it causes the walking beam (and horses head) of the pumpjack to move up and down. Weights are placed on the arms of the pumpjack and positioned to balance the weight of steel of the sucker rods. This reduces the amount of energy required to drive the pumpjack. The rods are pieces of steel (or occasionally fiberglass) which are threaded together to form a long steel pin which travels up and down the length of the well inside the tubing. At the end of the rod string is a pump barrel containing the pump components and the barrel is held in place in the tubing by a pump seating nipple. The pump is seated in the tubing and consists of two check valves. The travelling valve is connected to the sucker rods at the bottom of a plunger, and the standing valve is at the bottom of the pump barrel. The Traveling valve is so named because it travels, or moves, and the standing valve always stays in place as part of the pump barrel. The check valves of both these valves react to the pressure change seen in the pump barrel between the plunger and the standing valve.

When the horses head of the pumpjack moves upwards, the connected sucker rods move upward, and the plunger and travelling valve do as well. The ball of the travelling valve is then sealed and moves fluid up the tubing (and out of the well). At the same time, the pressure in the pump barrel drops, opening the ball of standing valve and allowing fluid to enter the barrel. With the horses head of the pumpjack moving down (the downstroke), the pressure in the pump barrel increases, sealing the standing valve and opening the traveling valve. Fluid then moves past the ball of the traveling valve and is ready to be moved out of the well on the next upstroke. This cycle continues over and over as the pumpjack moves up and down. The ball of the standing valves alternate on and off their seat (metal ring) allowing oil to move to the zone of lowest pressure.

Gas is best left out of a rod pump

It is critical that a rod pump is able to create a pressure seal between the ball and seat of the standing and travelling valves and between the plunger and barrel of the pump. In the event a well produces even a small amount of sand, this can cause erosion of the sealing surfaces, reducing pump efficiency. To help prevent this, there are numerous metallurgical options for the valve ball and seats ass well as material alternatives and tolerances for rings of the plunger all designed to better handle sand particles. The travelling and standing valve are able to open and close each cycle because of the pressure difference in each stroke direction, however, gas, unlike liquid, is compressible and the buildup of gas in a pump barrel can result in the gas compressing rather than flowing around the balls, known as gas lock. Gas locking can be prevented by allowing gas to flow up the annulus, and corrected by adjusting the stroke of the pumpjack so the travelling valve physically contacts the standing vale (tapping). A rod pump is a simple, robust design that has proven it's durability over time. There are alternative artificial lift methods, all well suited to different operating conditions, but the rod pump, powered by a pumpjack, is the quintessential oilfield symbol that will continue to produce for years to come.

You may also like

Oilfield review, 2016

The goal for 'Ballycatter Tech' is giving high value content and offering the best experience every day.