Other related articles

Where to Place an Offshore Platform Dive Support Vessel (DSV) DEG Reboiler (Diethylene glycol)

Hydraulic Cylinders

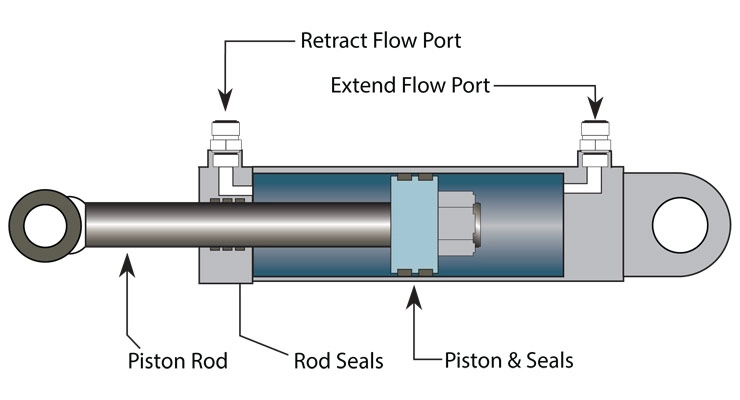

A hydraulic cylinder is a mechanical actuator that uses the power of pressurized hydraulic fluid to produce a force in a linear motion. It is commonly used in a wide range of industrial, mobile, and marine applications, such as construction equipment, manufacturing machinery, and marine propulsion systems. The hydraulic cylinder consists of several key components, including a cylinder barrel, a piston, a rod, and seals. The cylinder barrel is the outer tube of the cylinder, which contains the pressurized hydraulic fluid. The piston is a sliding cylinder that is located inside the cylinder barrel and is used to convert the pressure of the fluid into a linear force. The rod is connected to the piston and extends out of the cylinder, providing the linear motion of the cylinder. The seals are used to prevent leakage of the fluid between the cylinder barrel and the piston.

The cylinder barrel is typically made of high-strength steel, aluminum, or other durable materials that can withstand the high pressures and temperatures of the hydraulic fluid. The piston is typically made of a low-friction material, such as a polymer or a ceramic, which helps to reduce wear and improve the efficiency of the cylinder. The rod is typically made of a high-strength steel or other durable material and is designed to withstand the high loads and stresses of the cylinder. The seals are typically made of synthetic rubber or other durable materials and are designed to provide a tight, leak-free seal between the cylinder barrel and the piston.

The hydraulic cylinder is operated by pressurized hydraulic fluid, which is supplied by a pump or other hydraulic power source. The pressurized fluid is directed into the cylinder through a port in the cylinder barrel, and it acts on the piston, causing it to move, and thus producing the linear force. The fluid is then directed out of the cylinder through another port, and the cycle is repeated, producing the linear motion of the cylinder.

The Engineering specifications for the hydraulic cylinder are: Bore size : from 0.5" to 24" Stroke length : from 0.5" to 48" Working pressure : from 1000 PSI to 10,000 PSI Temperature range : from -40°F to 250°F Materials : Steel, aluminum, stainless steel, and special alloys Type of seal : U-cup, piston ring, rod wiper Mounting : Clevis, flange, trunnion Certification : ISO 9001, API 6A and API Q1 Hydraulic cylinders are available in various designs, such as single-acting and double-acting, and can be customized to meet specific application requirements. Single-acting cylinders have pressure applied to one side of the piston and rely on a spring or other mechanism to return the piston to its original position, while double-acting cylinders have pressure applied to both sides of the piston, allowing for both extension and retraction. In conclusion, hydraulic cylinder is a mechanical actuator that uses the power of pressurized hydraulic fluid to produce a force in a linear motion. It is commonly used in a wide range of industrial, mobile, and marine applications. The cylinder consists of several key components, including a cylinder barrel, a piston, a rod, and seals. The cylinder barrel is typically made of high-strength steel, aluminum, or other durable materials that can withstand the high pressures and temperatures of the hydraulic fluid. The cylinder is operated by pressurized hydraulic fluid, which is supplied by a pump or other hydraulic power source. Its design, engineering, and technology make it a great option for various applications that require linear force and motion.

You may also like

Image from https://www.cetparts.ca/hydraulic-cylinders/3044-telescopic-cylinder-250p.html

Image from https://www.mobilehydraulictips.com/business-end-hydraulics-cylinder/

The goal for 'Ballycatter Tech' is giving high value content and offering the best experience every day.