Frac'ing Basic

Hydraulic fracturing, or frac'ing is an effective mans of increasing recovery and production rate from an oil and gas well. This stimulation technique is used to increase the area oil and gas has to flow into a wellbore. Small diameter wells naturally become a choke point for fluid fow and by hydraulically fracturing the rock around the well, a more effective flow path can be opened up. The rock containing oil and gas is split (fractured) by applying hydraulic pressure. The pressure applied is high enough to exceed the tensile strength of the rock matrix, creating cracks in the rock. Fluid is also lost into the natural permeability of the rock and a viscous gel is used to reduce these losses. The fluid pressure and rate used to fracture the rock is accomplished by the use of pumps at surface. A well typically only requires one hydraulic fracturing treatment, so the pumping equipment is mobile and can be transported from well to well. In conventional frac'ing, the strength of the caprock (overlying geologic layers) and well construction (the steel and cement used in drilling the well) keeps the frac contained in the target zone. This is an important design consideration so the reservoir fluids stay in the original geologic horizon and don't leak off (into groundwater, for example).

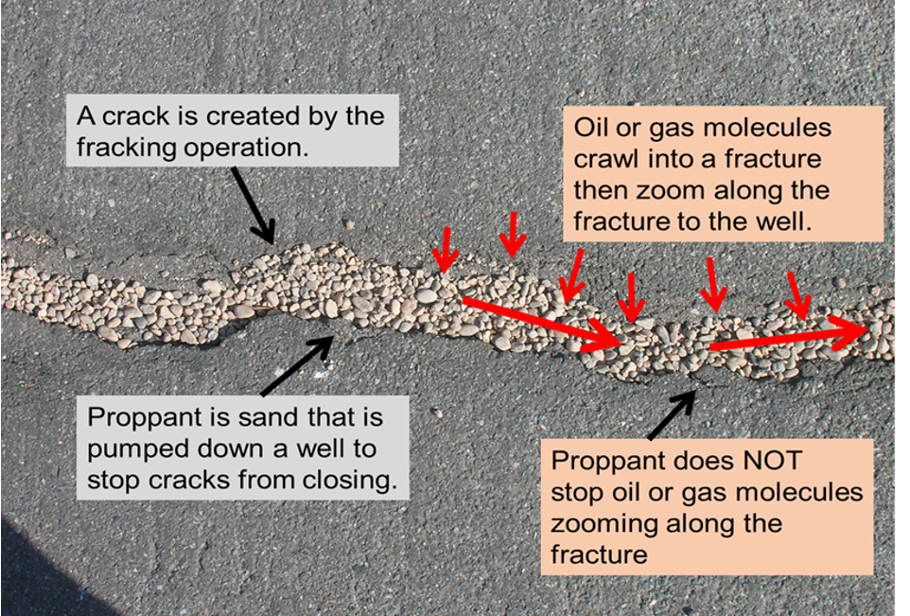

In brittle rocks like shale the rock is cracked (slickwater frac'ing), but in a more flexible rock like sandstone the frac wil seal back together when the pressure is removed. This can happen when pressure is bled off from surface, or if the fluid loss to the formation gets high enough that the pressure drops and hence the use of a high viscosity fluid (like the consistency of hair gel) to stop the pressure from dropping and the frac sealing. The pressure has to be removed at some point, but before that happens, proppant is placed in the open fracture to keep it "propped" open. Proppant is typically sand with a large grain size. The Sand grains stop the rock from coming back together when the hydraulic pressure is removed and the space between the sand grains create a convenient flow path for the oil and gas to flow towards the wellbore.

Frat jobs have been pumped from supply vessels

The combination of pumping horsepower, pressure, rate, viscosity and sand density all comes together in a very short timeframe. The variables are adjusted as the rock is fractured, fluid properties adjust, and pumping pressures and rates need to respond. Weeks (and sometimes months) of planning and preparation come down to a frac activity which, in some cases, can go from initiation to tip screen-out in a matter of minutes. Frac operations (especially slickwater frac'ing) have been implemented onshore, and these are the classic images of numerous tucks in a multi-stage job, but also occur offshore using existing platform infrastructure or with the use of a dedicated frac boat. There have also been hybrid activities where frac jobs have been pumped from the deck of a supply vessel. Regardless of the location, geologic horizon, well construction, number of stages, the importance of job design and planning is critical to ensure a successful job. By controlling the energy of the activity, through design and execution, hydraulic fracturing operations are an effective tool in increasing resource recovery.

You may also like

From Forbes, The Pursuit of Proppant by Ian Palmer

The goal for 'Ballycatter Tech' is giving high value content and offering the best experience every day.