Where to Place an Offshore Platform

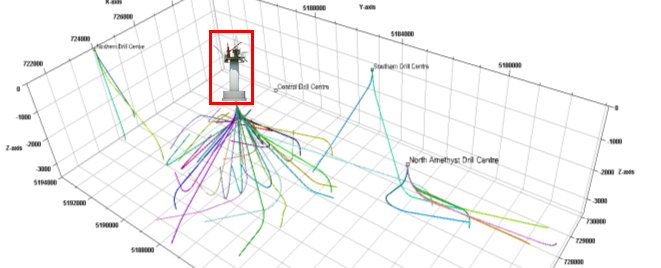

When a major oil and gas operator wanted a new concrete gravity based platform placed in their existing subsea field, they asked us to figure out where to put it. At first it may seem like an easy task, pick a nice flat piece of seabed and job done. It is not that simple, however, and it took a multi-disciplinary team to get the optimum solution. Like all engineering issues, it is all about weighing the trade-offs between alternatives. Factors to consider in the placement of an offshore platform include drilling and completion costs, subsea infrastructure, and environmental impact, to name a few. These factors will impact the longer term viability of an offshore asset and it’s overall operability as infrastructure is added in the field. The drilling and completion costs are the most obvious to have be directly impacted by the surface position of an offshore platform. Here the overall drill and complete cost, as well as ability to reach geologic targets is based on the surface location of the platform, i.e. the starting surface location for all wells. Typically, platform placement is as close to the “center” of the pool as possible to enable the easiest options to access all parts of the structure, however, factors such as the desire to have horizontal completions, specific azimuths through a stress field, or a secondary geologic prospect, may move the platform from the “default” bullseye position. It is important to have an asset development plan from subsurface available (as mature as possible), to plan completions and trajectories for potential platform positions.

When placing an offshore platform in a greenfield development, the drilling and completion factors will likely dominate, but the situation becomes more complex when a platform is being installed in a field under development. Environmental areas such as decommissioned assets in use as reefs, or commercial fishing or navigation channels reduce the alternatives for platform positioning. While issues like spud cans and approach quadrants are important factors with adjacent platforms, subsea infrastructure poses additional constraints as the existing drill centers, flowlines and manifolds can be in positions which may interfere with platform placement. When dealing with subsea infrastructure, it is important to remember the infrastructure that is transient. For example, semi-submersible MODU’s which are not dynamically positioned will require space reserved for anchors. These positions look quite clear on a map, but it is important to remember that anchors may need to be handled and re-positioned occasionally, and these anchor handling vessels require room to work. A platform set in position can greatly interfere with these operations if not considered in the design phase. In shallower water depths there may be special environmental conditions such as fish habitat or commercial fishing which should be given adequate space. If the platform is planned to provide power to subsea infrastructure, the cable distances may play a role. Subsea instrumentation or fibre-optic cables may also be a consideration, as the ability to make a short connection to a subsea fiber optic cable can open a world of data gathering and analytic opportunities. Some of the most important data to gather in an oil and gas asset can be seismic data, and most likely 3-D seismic has already been shot in a field where a new platform is being installed, however, the seismic lines should also be mapped in the event that a future 4-D (or pseudo 4-D) seismic campaign would occur. Placing the platform on an existing 3-D seismic line can be compensated by the seismic vessel altering course around the platform, and using post processing to correct the offset, but if this can be avoided it will provide higher quality data in the future. When orienting the platform factors such as prevailing winds determine platform heading, but below the water line, the environment of the subsea is just as important in determining the final position of an offshore platform. It takes an integrated team, looking at the position question with a view to as many possible current and future operations, development, and exploration activities as possible. This multi-disciplinary approach can lead to position adjustments which can enable significant opportunities in the future, thus the effort to future-proof an offshore platform position requires a focused, diverse team.